2020 © DHCAE Tools GmbH I Contact I Disclaimer I Data Protection

Engineering and

Software Solutions

for CFD and FEA

Your are here: Examples > Case Studies

DHCAE Tools’ expertise

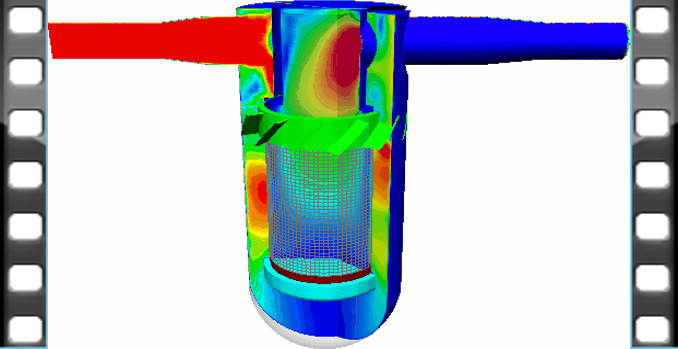

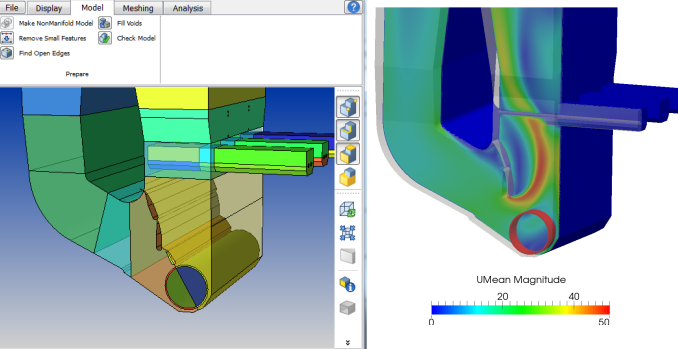

We have a vast experience and expertise in solving complex CFD tasks from various sectors for a targeted design or optimisation of products and processes.

Industry projects

During our 20 years in the field of CFD services and OpenFOAM extensions, we have successfully completed a large number of CFD projects for various industries. Just click on the icons to learn more about our CFD engineering solutions and software tools in your industry.

Icons by Icon8